DiaMet

April 10, 2019

MicroMet

April 10, 2019HelioMet

₨0.00

Measurement device to determine the engravability of copper cylinders. The measured value informs about the structure and ductility of the copper.

Simple, reliable engravability measurement

HelioMet was specially developed for engraving needs in the gravure printing industry.

Until now, the only criterion for engravability of gravure cyl inders was hardness. In addition to hardness, however, the structural composition of the layer to be engraved has a major influence on the cutting behavior as well as the lifetime of engraving styli.

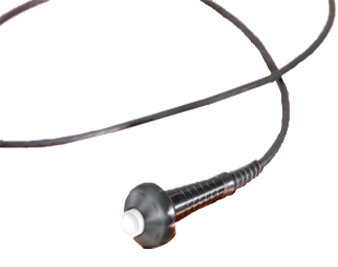

This device uses a specially developed probe to measure the electrical conductivity of the layer. The result is information on how well a metal conducts electrical current as well as on its composition and structure, including its microstructure or mechanical properties.

The standards developed by K.Walter enable good evaluations regarding engraving behavior. According to the measurement values the electroplating processes can be influenced, espe cially the deposition quality of the tanks. This leads to better production quality and stability.

Overview of features:

Latest measurement equipment technology

Nondestructive measurement with eddy current method

Reliable determination of reproducible measurements>

Rapid identification of material properties

Allows deeper electroplating process control

Simple operation

Extensive memory capacity

Technical data:

Measurements comply with ASTM E 1004 and DIN EN 20041 standards (eddy current method)

Measurement range: 0.3 63 MS/m or 0.5 108 % IACS

USB MiniAB connection for printer or PC

2100 mAh battery pack, 110 230 V plugin power supply unit

Individual consideration of electrical conductivity temperature coefficient

Automatic shutoff

Alarm function for absolute temperature difference

Audible signal for measurement recording and when tolerances are exceeded

Operating temperature: 0 °C to +40 °C

Graphic display / touchscreen in 8 languages: DE, CZ, GB, ES, FR, IT, PL, TR

Weight with battery: 600 g

Dimensions in mm (L x W x H): 180 x 90 x 40

Part Number: 215040